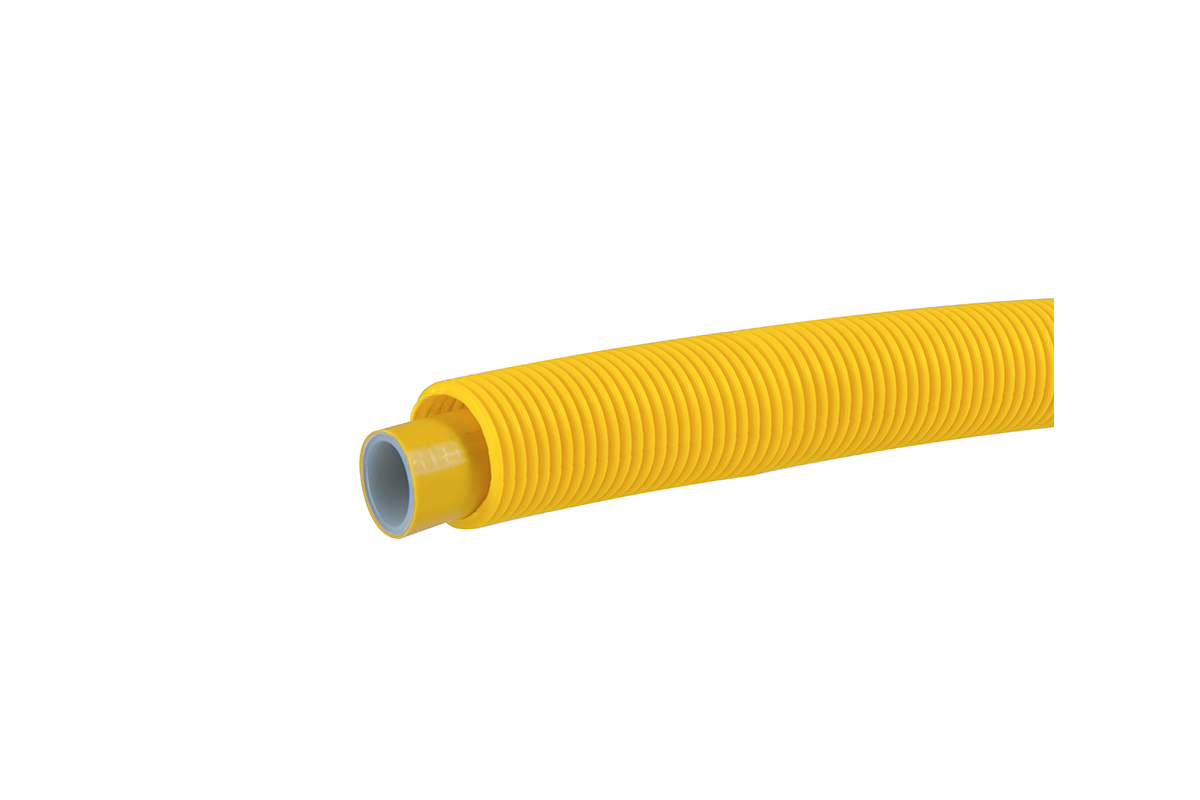

TDM BRASS multilayer pipes are available in rolls and in bars of various lenghts. They are produced in accordance with the regulation UNI EN ISO 21003-2:2011 concerning multilayer piping systems for hot and cold water installations inside buildings, and with the regulation UNI 11344:2016 concerning metalplastic multilayer piping systems for indoor installations for the conveyance of gaseous fuels.

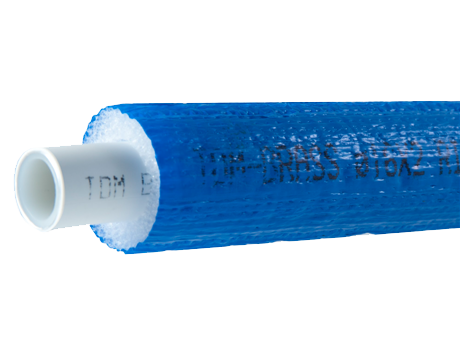

In addition, TDM BRASS supplies also PE-Xb multilayer pipes pre-insulated with closed-cell expanded polyethylene and polyethylene covering film, in compliance with the law 10/91. Insulated pipes are suitable for plumbing and heating systems.

TDM BRASS LINE 1800 gathers the multilayer pipes for water and gas heating systems and the related accessories. TDM BRASS MULTILAYER PIPE is composed of 5 layers:

- Cross-linked polyethylene PE-Xb

- Adhesive resin

- TIG butt welded aluminum

- Adhesive resin

- Cross-linked polyethylene PE-Xb

The combination of these materials allows to go beyond the individual limits of each one. The downsides of metal, such as vulnerability to corrosion and encrustations, rigidity, and high pressure drops, are neutralised by the polyethylene layer in contact with the fluid. Similarly, the drawbacks of plastic, such as high permeability to gas and UV rays, high thermal expansion coefficient, and instability, are neutralised by the aluminum layer placed between the two PE-X layers. TDM BRASS has selected the most advanced product technologies for its pipes, equipped with internal and external PE-X and with a butt welded aluminum core. Unlike other processes such as welding of overlapping edges, butt welding ensures a top-level protection against the risk of damages during bending operations, due to the intrinsically uniform thickness of the pipe. The total control over thickness and diameter of each layer, along with the employment of suitable adhesive resins, allows to perfectly join the various layers together, thus making the pipe homogeneously resistant.

THE ADVANTAGES OF ALUMINIUM

- WORKABILITY: Unlike PE-X pipes, thanks to its aluminum core multilayer pipe does not have shape-memory effect: once it has been bent and formed, it maintains the new shape.

- DIMENSIONAL STABILITY: The resistance that distinguishes aluminum acts against the crushing caused by external loads.

- FLEXIBILITY, INALTERABILITY, AND STABILITY: Multilayer pipe bends as easily as a plastic pipe, but it maintains the desired shape like metal pipes do. It is possibile to make several operations on the pipe without damaging it. The bending radius can vary up to a minimum of five times the diameter of the pipe without altering its section.

- LOW LINEAR EXPANSION: The comparative table reported below shows that the thermal expansion coefficient of the multilayer is similar to that of metals and much lower than that of plastics.

- BARRIER TO OXYGEN: The aluminum layer is impenetrable to oxygen and light, and protects the internal plastic layer against their effects.

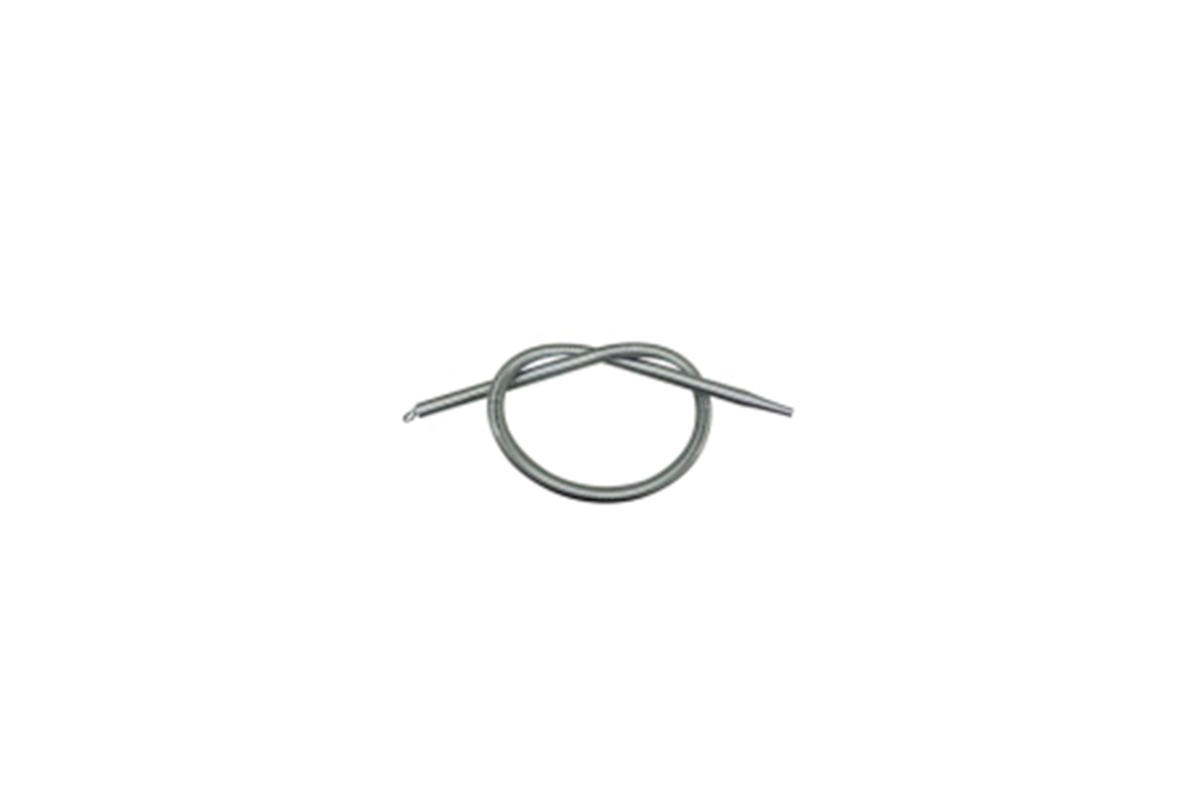

- BENDING: By hand: 5 times the external diameter of the pipe; With a specific pipe bending spring: 3,5 times the external diameter of the pipe